Infrastructure

Heat Treatment is operation in TEIL which include continuous and batch type gas carburizing, gas nitriding and induction hardening facilities.

Heat treatment equipment also includes Tempering furnaces, Rotary Hearth furnaces with Endothermic gas generator to provide & maintain controlled atmosphere inside furnaces.

Two PLC based continuous carburizing furnaces are present for Heat Treatment of hypoid, Spur gears and shaft, with double track and computerized control. Both furnaces are equipped with Oxygen Probing system to control internal atmosphere of furnaces to ensure better quality products. These are first of their type in Pakistan.

To maintain flatness, ovality & other dimensions quenching PRESSES are present for hypoid and other gears.

5 Batch Type Sealed Quench furnaces for Heat Treatment of all types of gears, shafts and pinion. Each furnace has oxygen probing system for controlling surface carbon potential of the components during the process which ensures a high standard of quality.

Nitriding Furnace: Electrically heated furnace for Gas Nitriding of Planetary Ring gears is available.

Rotary Hearth Furnace: Gas fired Rotary Hearth furnace for Hardening of gears in inert atmosphere

Continuous and batch type tempering furnaces having temperature range from 0°C - 300°C.

Shot blasting machines are for gears and shafts. The bed dia. of machines ranges from 8 to 10 ft with dust extractor unit.

Manually operated sand blasting machines to clean left over scale in narrow corners.

There is a line of phosphating process used for gears of differential casings and Couplers.

Endothermic gas generators for constant supply of atmospheric gas to Gas Carburizing Furnaces for maintaining controlled atmosphere inside the furnaces.

To cater the ongoing gas load shedding crisis & ensure continuous production, Synthetic Natural Gas plant is in working to supply uninterrupted gas supply to the furnaces.

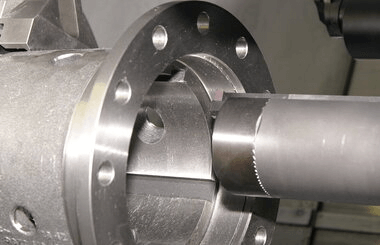

Our special production facility, utilizing the most efficient broaching machinery and specialized machines for surface, internal and "blind" hole broaching in broad capacities is available for customer applications and contract broaching.

Services Available

- Surface Broaching

- Internal Broaching

- "Blind Hole" Broaching

- Pot Broaching

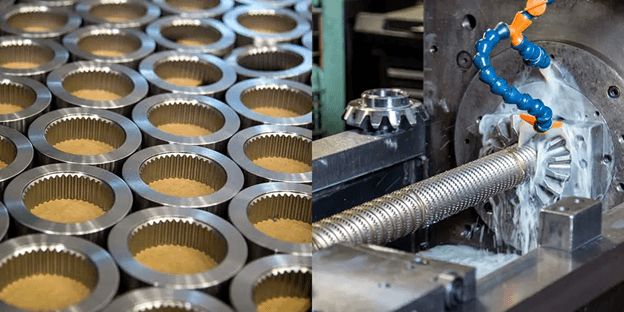

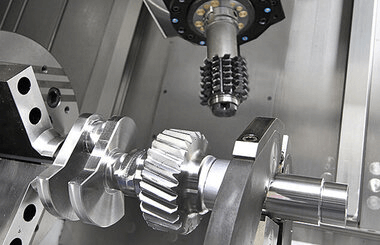

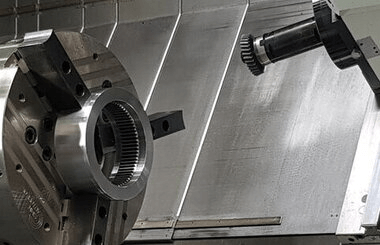

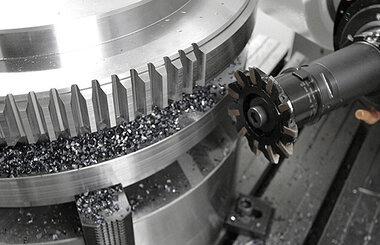

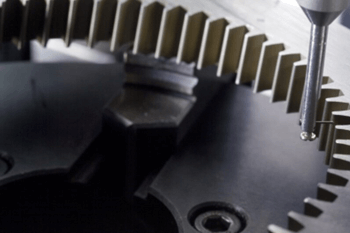

Gear cutting processes are a combination of various machining processes with both geometrically defined and undefined cutting edges to produce positive connections on components. These include splines, notched, keyed, helical, and involute splines. Special technologies such as hobbing, peeling, turning, or shaping are used.

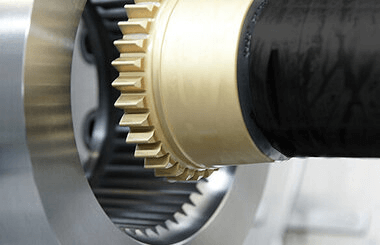

Gear hobbing is a highly productive milling process to produce gear teeth, primarily for gears, which are produced by hobbing a special gear hobbing tool on the workpiece. We can integrate gear hobbing on our horizontal as well as on our vertical production and turning-hobbing centers, and thus produce almost any number of teeth and helix angles for a wide range of workpiece sizes.

Hob peeling, also known as power skiving, is a high-performance gear cutting process used for high production manufacturing of internal and external gears – particularly splines, helical gears, and spur gears. The process, in which the workpiece and tool axes must always be at a specific angle to each other, is characterized by its extremely high productivity and high cutting speeds compared to shaping or conventional gear hobbing.

Roller shaping, a sub-process of gear shaping, is a versatile combined process of generating and shaping motion for the production of any internal, external, or special gears. Since it is a highly specialized process, it is often used for smaller batch sizes or unique workpieces for which, due to geometry and collision, gear hobbing or gear shaping is not suitable.

Gear shaping, often referred to simply as shaping, is a flexible machining process based on straight-line shaping movements with a specific cutting edge to produce straight internal, external, and special gears as well as grooves. The process is mapped either by using driven special shaping tools or by lateral movement of the tool aggregate used. A distinction is made between the use of shaper wheels or single shaper tools.

Invomilling is a new, manufacturer-patented gear cutting process which is particularly suitable for the extremely flexible production of external gears and keyed gears. With this process, it is possible to produce a wide variety of gear profiles with only one standardized tool set. As a rule, side milling cutters are used which reproduce both roughing and finishing processes. It is therefore more suitable for small and medium series, but is extremely productive and economical in this field. It should be emphasized that this process can also be used to easily produce gears with a very large module.

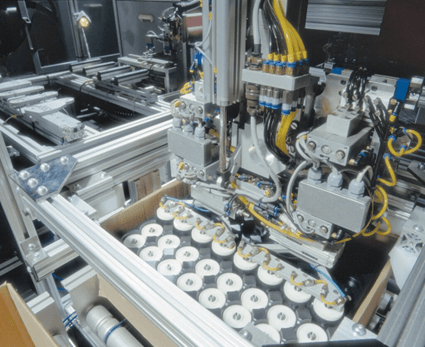

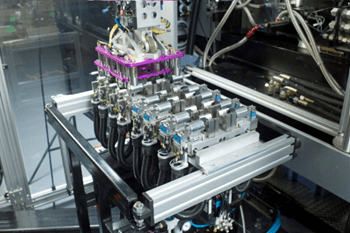

For many years, TEIL has embraced the science of decoupled scientific molding with extensive training and collaboration with RJG. The proper execution of scientific molding is critical to maintaining and documenting consistent quality production for a gear with high tolerances and demanding structural and dimensional stability requirements.

- Every prototype and production cavity developed includes a pressure sensor, which ensures minimum variability in gear dimensions and material integrity.

- Molding processes are based upon the plastic behavior in the cavity – cavity pressure curves are date stamped and stored on the company server.

- If a gear fails to meet cavity pressure tolerances, it automatically gets rejected.

- Once approved, gears are then picked by a robot, placed on a conveyor, or placed in a carton.

Our vision for the future of automation at TEIL is Industry 4.0 data analytics, which will facilitate the optimization of processes. From prototyping to production, TEIL will always ensure all your molded gears perform consistently with the help of our data-driven scientific molding process.

At TEIL, we have gear metrology equipment to validate and monitor all critical gear characteristics, from the initial prototype all the way to large volume production.

Our high-quality equipment, personnel training, and top-of-the-line systems are here to assure you our gears meet all your dimensional and structural requirements. Our metrology lab offers the most comprehensive quality assurance, backed up , to ensure your gears are made to your exact specifications. Resources we utilize include:

- Quality Assurance Laboratory

- Gear Metrology Laboratory

- Analytical Gear Inspection

- Dual Flank Composite Gear Inspection

- Gear Data Capability Study

TEIL is always innovating, and our ongoing pursuit of integrating automated manufacturing practices is what keeps us at the top of our game.

With consistent large volume gear production, we need to keep track of it all with documented automated processes with a focus on high-volume gear manufacturing. Our automated systems allow for repeatable quality and reduce the overall production costs. Highly-skilled engineers ensure every project is best optimized with the right technology while being supported by our team who performs ongoing quality checks.

The goal of our automation is to minimize human decisions and provide consistent large volume production that meets your quality and technical requirements.